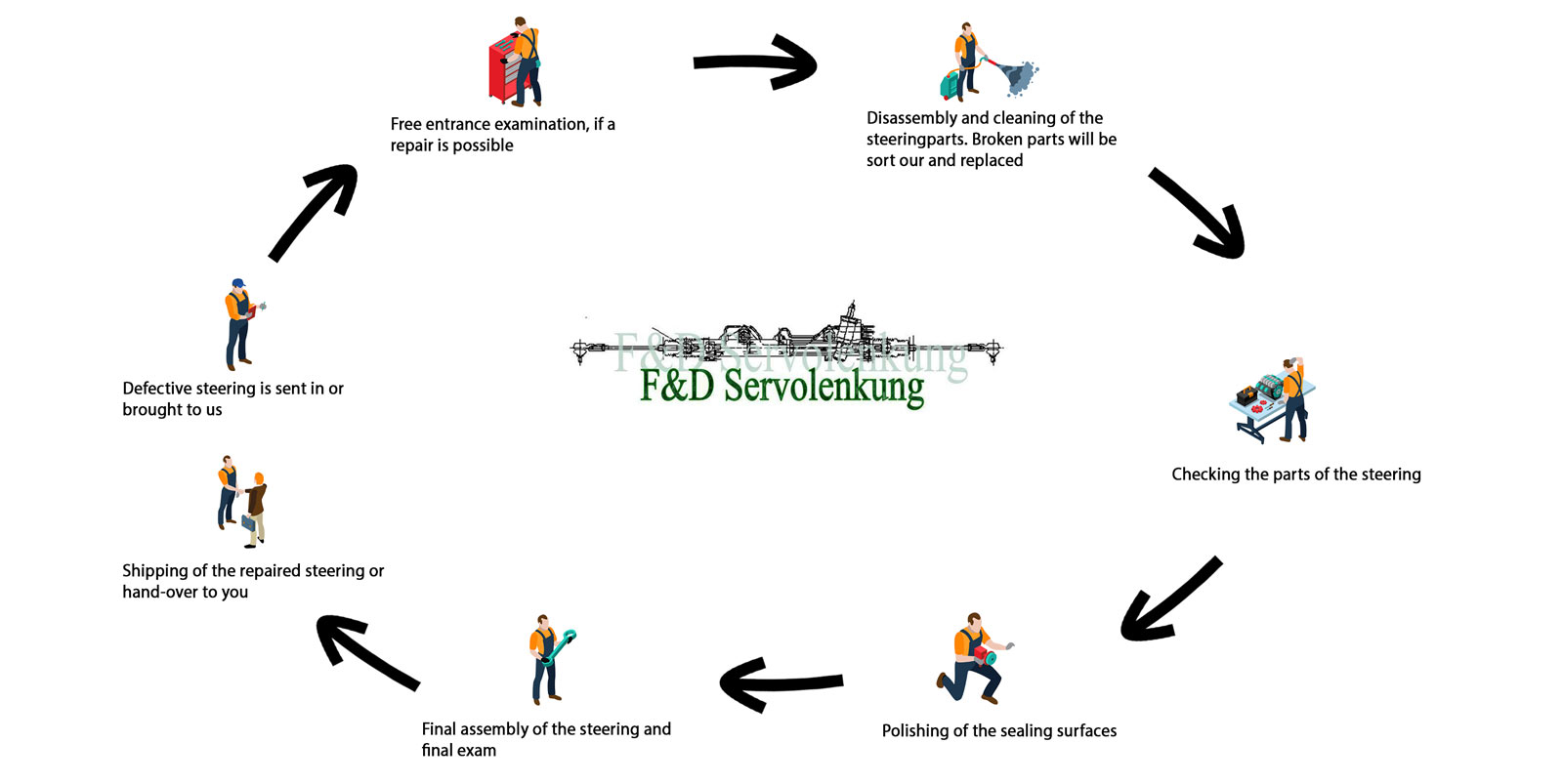

Repair process & advantages

The repair

The detailed repair process

Goods receipt of a recirculating ball steering

1. Creation of the run card, customernumber and note of any attachments

2. Visual inspection for damage

3. Check adjustment attempt and backlash

4. If the game is too big, cancel and inform the customer

5. After approval, order spare parts

6. Remove attachments. In a difficult dismantling, e.g. from

the steering arm (before disassembly) on the resulting

inform about the additional costs

Repair of a recirculating ball steering

1. Complete disassembly of the steering

2. Cleaning all steering items

3. Disassembly of all seals

4. Visual inspection of the items. Check all bearings to play and function

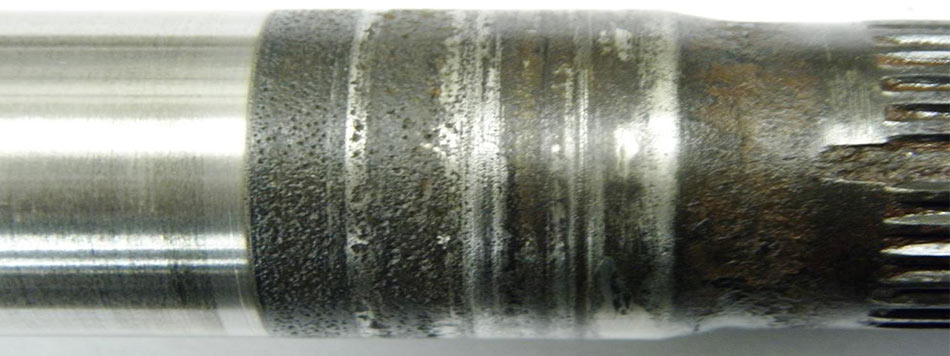

5. Polishing the sealing surfaces

6. Assembly of the new seals

7. Assembly and adjustment of the steering

8. Mechanical test of the steering torque and backlash

9. Pneumatic test for external leaks

10. Hydraulic test for internal and external leaks and exam of

the function

11. Degrease and paint the steering

12. Wrap up the steering and any additional parts that may be present

13. Inform customer about completion of repair and

request the shipping document

Goods receipt of a rack and pinion steering

1. Creation of the run card, customernumber and note any attachments

2. Visual inspection for damage

3. Check adjustment attempt and backlash

4. If the game is too big, cancel and inform the customer

5. After approval, order spare parts

6. Remove attachments.

Repair of a rack and pinion steering

1. Complete disassembly of the steering

2. Cleaning all steering items

3. Disassembly of all seals

4. Visual inspection of the items. Check all bearings to play and function

5. Polishing the sealing surfaces

6. Assembly of the new seals

7. Assembly and adjustment of the steering

8. Mechanical test of the steering torque and backlash

9. Pneumatic test for external leaks

10. Hydraulic test for internal and external leaks and exam

of the function

11. Degrease steering and paint if desired

12. Wrap up the steering and any add-on parts that may be present

13. Inform customer about completion of repair and

request the shipping document

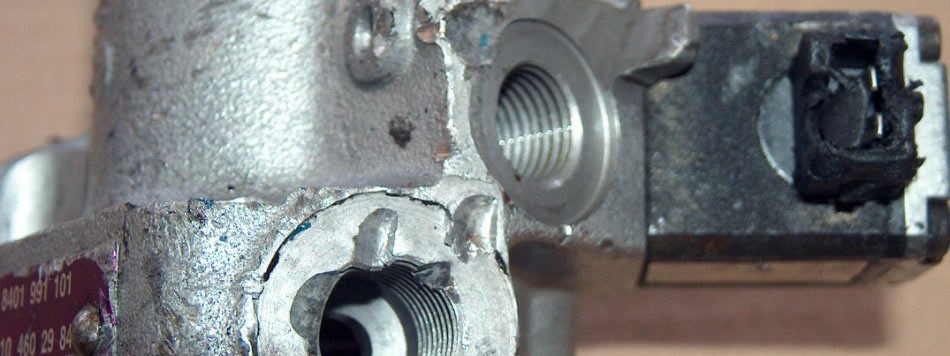

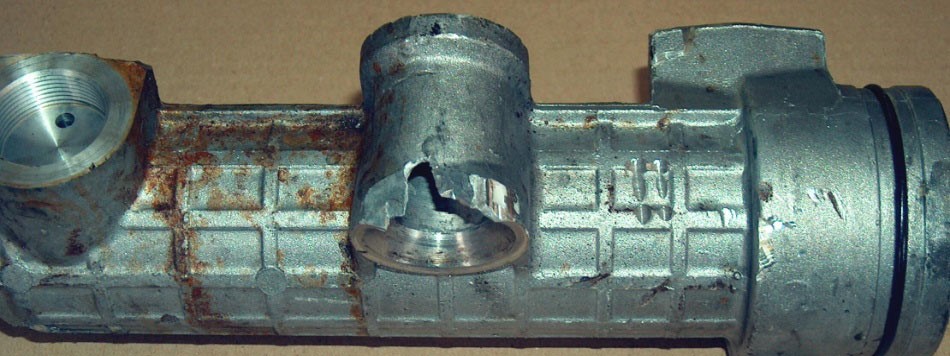

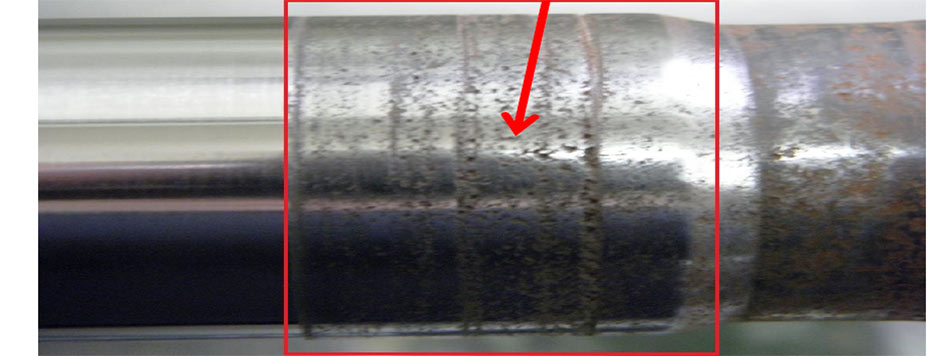

No longer repairable damages

In most cases it is possible to replace individual components – just contact us!

The steering should be wrap up in such a way that it does not damage or lose oil.

The following information should be provided to us:

Details of the vehicle e.g. Manufacturer and type

Error description of the steering

Phone number and return address

On request, we will pick up the steering from any shipping service provider. Please contact us in advance!

What is the advantage by repairing from F & D steering?

By repairing you will receive a timely repair of your vehicle!

You receive a cost-effective factory processing of your broken steering

Direct processing at the conditioner

Therefore no intermediate trade and additional costs

Fast processing, directly by us or within 3 working days

Poor spare parts procurement for older vehicles

For many old vehicles it is difficult to get corresponding replacement parts in the trade. On the Internet, so-called “new parts” are often offered very cheaply, but these are usually no original spare parts, but dangerous replicas from the Asian region. With the installation of such a steering many vehicles even lose their approval!

However, with a 1 to 1 repair this is not a problem. In almost all cases, you can get the necessary original repair kits for the steering. That is why we only use spare parts which meet the corresponding specifications of the manufacturers.

No longer obtainable vintage parts, e.g. for Porsche, Rolls Royce or Ferrari are manufactured or rebuilt by our professional workshop!

Repair request

Create now a repair request for your broken steering and we will contact you as soon as possible